Cam runners are significantly different from conventional needle bearing style cam followers.

(Click here for Product Specifications)

General Characteristics

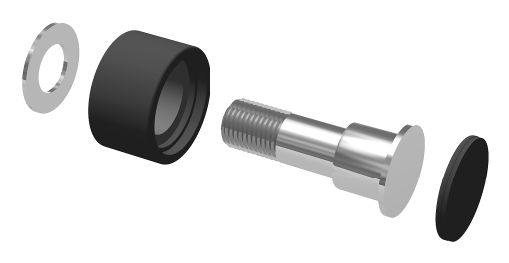

Cam Runners are manufactured with a composite synthetic tread and stainless steel stud. The composite tread consists of two different synthetic materials chosen to provide optimal characteristics for the outer wear surface and the inner bearing surface.

The two synthetic parts are molded together to form a single mechanically bonded assembly that is mounted on the stud, eliminating the need for conventional seals and lubricants. The outer tread material offers high mechanical strength while the inner bearing material provides high lubricity.

The stud provides optimum life and corrosion resistance. Tread bearing wear is critically dependent on the hardness of the mating surface.

When this assembly is used as a direct replacement for a conventional cam follower, the life will be optimized if the cam or other mating surface is within the range of 55 - 60 Rc. Softer or harder materials may result in decreased life, particularly under high loads. The mating surface must be free of grease, oil and abrasive contaminants.

This assembly is dimensionally interchangeable with conventional steel cam followers. Because of its unique construction, comparable load ratings are not applicable. In order to guide you in choosing applications, extensive testing has been utilized to develop life expectancies based upon continuous duty testing at various speeds and loads. In continuous duty operation under identical loads and speeds, the Cam Runner has been found to outlast conventional steel cam followers by an average of 10 times!

Bearing to stud clearance is greater than for needle bearing designs and will increase during early use and will stabilize after ”wearing in“.

Advantages

- No lubrication required – ever!

- Non sparking and low electrical conductivity

- Thrust load tolerant

- Extended life, ideal for difficult-toservice-operations

- No lubricant leakage to contaminate your process

- Quiet operation resulting from no internal moving parts

- Wide range of operating temperatures

- ISO 9001 compliant

Not recommended for ambient temperatures above 250° F, highly abrasive applications or repeated heavy shock loads. This product is protected by U.S. patent and other patents pending.